[ad_1]

Avicarvil is a number one poultry producer, processor and retailer in Romania with an annual farming and processing capability of over 30 million chickens/12 months. The corporate plans to double this capability within the years to come back by constructing a greenfield processing plant in shut collaboration with Marel.

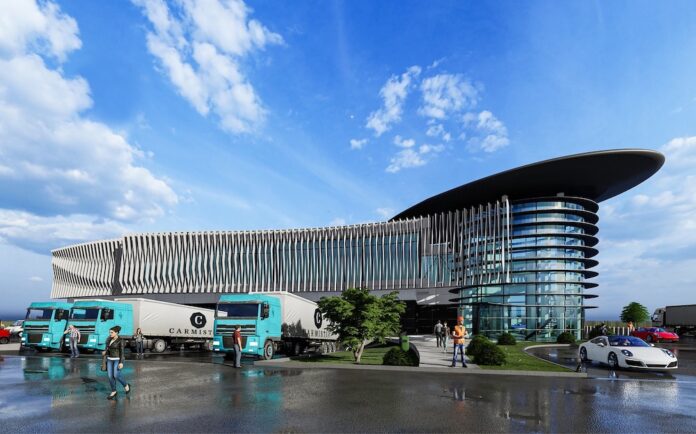

In Vâlcea County, Avicarvil will construct essentially the most fashionable poultry processing plant in South-Jap Europe. Protecting an space of 25,000 m2, it is going to be the most important rooster meat manufacturing unit in Romania.

First selection

The Avicarvil plant wanted to increase to make sure competitiveness in opposition to worldwide competitors, producing extra rooster of upper high quality. Andrei Brumaru, govt director of the overarching Carmistin Group, explains, “For the most effective outcomes and the most effective return on our funding, we determined to cooperate with Marel. For our new plant, we in contrast the effectivity of the traces in our two present processing crops. Marel’s line was clearly superior and our first option to equip our third processing plant with a capability of 13,500 bph.”

The brand new venture

The automated processing traces embrace robotization with Marel’s RoboBatcher. “The RoboBatcher within the filleting line makes a giant distinction within the pace and accuracy and ensures return on funding. By combining robotics and software program, RoboBatcher optimizes the processing time, high quality and security of our merchandise. As well as, Innova software program will assist us make data-driven, well timed choices, cut back prices, and improve our competitiveness.”

Sustainability tendencies

“Our investments goal to mitigate local weather change. We implement methods and applied sciences to optimize vitality use and water consumption. Marel Water Remedy will construct an revolutionary system for accumulating, treating and reusing water, absolutely complying with the rules in power. The numerous quantity of recycled water returning will lead to 80% much less water consumption,” says Andrei Brumaru.

The method

In Avicarvil’s new plant, the method begins with ATLAS, essentially the most sustainable and humane stay fowl dealing with system within the business. That is adopted by Marel’s gorgeous, scalding, plucking and evisceration options, together with the brand-new, clever Nuova-i eviscerator. The first course of is monitored real-time by IMPAQT software program. After mixed in-line immersion and air chilling, merchandise are reduce up in two ACM-NT traces and deboned in three AMF-i breast filleting methods. Then 5 Multihead Weighers and a RoboBatcher batch and pack the merchandise. Marel checkweighers and labelers end the method.

Extra data: marel.com/poultry or carmistin.ro

[ad_2]